Product design and drawing modificationKwan Tat has an engineering drawing team that provides professional advice on the size and function of your product or part。Quickly generate 2D and 3D drawings for your parts simultaneously。The SOLIDWORK, PROE, and AUTOCAD we use are the three major software commonly used in the industry。

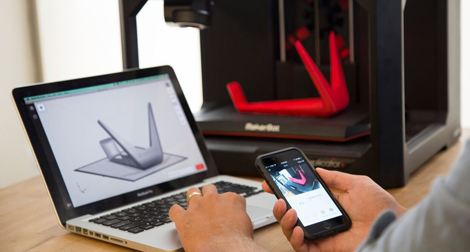

Product design and drawing modificationKwan Tat has an engineering drawing team that provides professional advice on the size and function of your product or part。Quickly generate 2D and 3D drawings for your parts simultaneously。The SOLIDWORK, PROE, and AUTOCAD we use are the three major software commonly used in the industry。 Template developmentSample production is an important step before mass production。When customers need it, we will provide professional opinions and suggestions to enable your product to be produced faster and at a lower price.。We have 3D printers for PLA and ABS, and depending on the situation, we will also provide simple mold production templates for customers。

Template developmentSample production is an important step before mass production。When customers need it, we will provide professional opinions and suggestions to enable your product to be produced faster and at a lower price.。We have 3D printers for PLA and ABS, and depending on the situation, we will also provide simple mold production templates for customers。 Mold and fixtureA well designed mold can reduce production time and cost。Our team and engineers with many years of experience,Tailor one of the best molds for different types and raw materials of products (such as stamping molds, hardware molds, plastic molds, etc.)。

Mold and fixtureA well designed mold can reduce production time and cost。Our team and engineers with many years of experience,Tailor one of the best molds for different types and raw materials of products (such as stamping molds, hardware molds, plastic molds, etc.)。 Lathes and punchesWe provide different types of hardware processing services。Our factory provides hardware processing services including lathes, milling machines, drilling machines, punch machines, etc。These are all common processes in the industry。In addition, we also provide CNC machining centers to handle high-precision and demanding products and components。

Lathes and punchesWe provide different types of hardware processing services。Our factory provides hardware processing services including lathes, milling machines, drilling machines, punch machines, etc。These are all common processes in the industry。In addition, we also provide CNC machining centers to handle high-precision and demanding products and components。 InjectionWe will recommend the most suitable plastic raw materials based on customer requirements and product characteristics。We provide injection molding services and can produce products with different plastic materials such as PVC, PE, PP, PA, POM, etc。

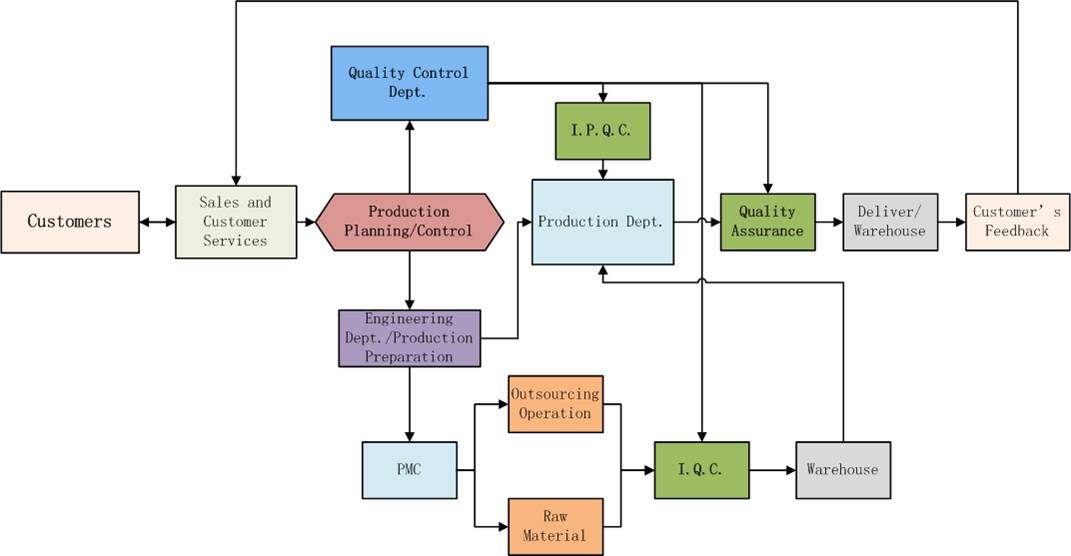

InjectionWe will recommend the most suitable plastic raw materials based on customer requirements and product characteristics。We provide injection molding services and can produce products with different plastic materials such as PVC, PE, PP, PA, POM, etc。 Assembly and testingAfter production is completed, product assembly is an important step in determining product functionality and integrity。Different levels of testing and quality monitoring can reduce the chance of product errors。Our well-trained team and quality control system have brought the quality of our products to a higher level。

Assembly and testingAfter production is completed, product assembly is an important step in determining product functionality and integrity。Different levels of testing and quality monitoring can reduce the chance of product errors。Our well-trained team and quality control system have brought the quality of our products to a higher level。